When we were developing all our sustainable packaging options we made sure we didn’t compromise at all on quality or performance. Your products will have the same shelf life as conventional pouches. Sustainability is critical for our planet’s survival. And everyone is on the same page.

The key drivers for increasing demand for sustainable packaging.

Rigid packaging containers such as composite carton boxes, glass jars or bottles, aluminum cans or rigid plastic containers are in decline as packaging alternatives. This is because they require considerable resources to produce and leave a larger carbon footprint. Not only that, such packaging options also require additional labeling.

Flexible packaging is lightweight, making it easy to transport and store. But that’s not all, its unique structure means that artworks can be printed directly onto it, and product contents can be visible. This lends it greater shelf appeal and helps drive customer trust at the point of sale.

When it comes to sustainability and small to medium print runs, there’s no better option than digital printing. As no print forms are required, you can order as small a quantity as you need, and we can personalize your packaging down to the smallest detail. The only limit is your creativity!

We are increasingly moving toward a circular economy, where we are turning away from the old “take, make and dispose” model to one where recycling is key. Here at lprint we are playing our part by making sure all our packaging is recycled and recyclable.

For us, it’s not enough to just make sure that our packaging is sustainable. Why don’t you join us in planting a tree for 100 every pouches we sell.

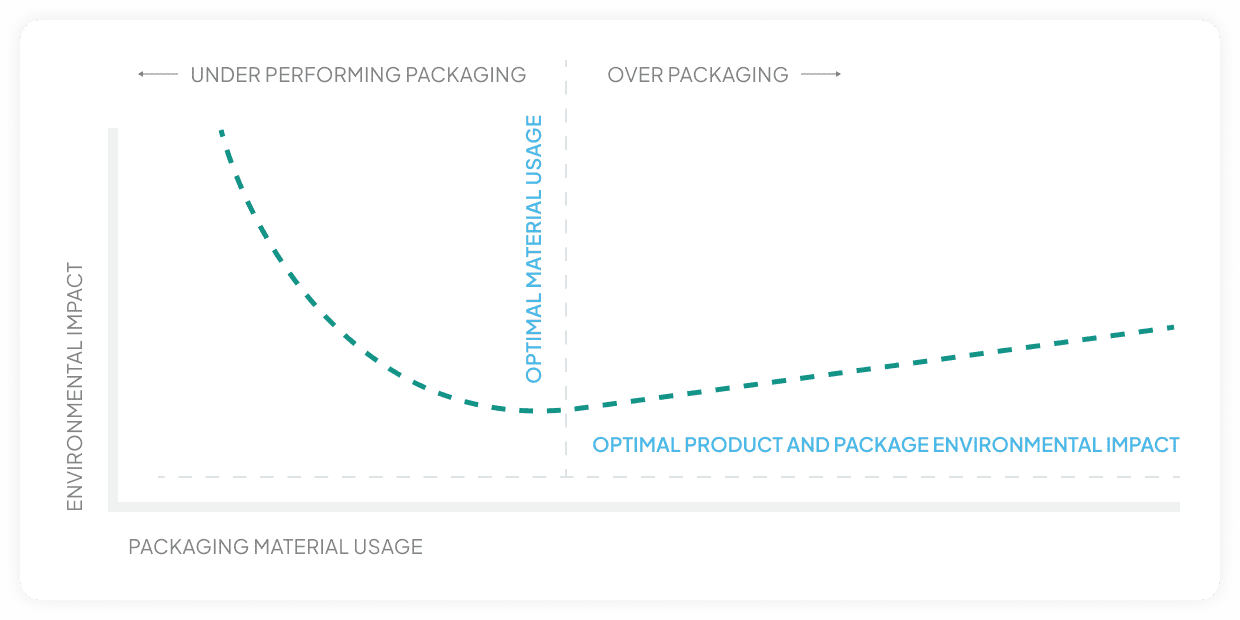

The simple but widely held opinion on packaging suggests that less packaging is always better. Why? Well, the argument would be that fewer resources are then needed. But this is not the whole picture. Well designed and produced packaging protects and extends product shelf life, meaning less food waste and a reduced carbon footprint. Of course, if the packaging is poor, then the opposite is true. So, what’s needed is for a delicate balance to be reached between the amount of resources invested in packaging and the resources saved through the protection it provides.

We understand that you might be new to questions of packaging and sustainability. And it can all get quite confusing quickly. That’s why we are happy to dedicate our time to helping you navigate through it all. Contact us for a free consultation and we’ll help you come up with the best result for your business.

You still have active cart items in this language, if you want to switch to the other language, cart contents will be deleted.

You can only reorder items that were ordered in the same language/currency combination you are currently in.